Introduction

The FCC800 Coriolis Mass Flow Meter is a high-precision instrumentation solution designed to deliver simultaneous measurements of mass flow, density, and temperature.

Engineered to withstand the rigorous demands of maritime and industrial environments, this device operates on the Coriolis principle to provide direct mass measurement without the need for external compensation.

Its robust construction and versatile design make it an essential tool for precise fluid management in sectors ranging from marine transport to chemical processing and pharmaceutical manufacturing.

Working principle

The FCC800 Coriolis flow meter operates by leveraging the Coriolis effect to achieve exceptional measurement accuracy:

-

Vibration Induction: The meter’s internal tubes are driven to oscillate at a resonant frequency by an exciter.

-

Coriolis Force Generation: As fluid flows through these vibrating tubes, it generates Coriolis forces that cause a phase shift or "twist" in the oscillation. The degree of this twist is directly proportional to the mass flow rate.

-

Signal Processing: High-sensitivity sensors detect these minute phase shifts. The onboard processor analyzes the data to calculate mass flow, density, and temperature in real-time, converting them into standard output signals for system integration.

Key features

Engineered to deliver precision where it matters most, the FCC800 Coriolis flow measurement integrates the following capabilities to streamline your operations and ensure measurement confidence:

-

Multivariable Measurement: Capable of directly monitoring mass flow rates, medium density, and process temperature in a single unit, eliminating the need for multiple instruments.

-

Marine-Ready Durability: Built with an IP67 protection rating and high vibration resistance, ensuring reliable performance in harsh offshore and shipboard conditions.

-

High Precision: Offers flow accuracy options up to Level 0.15 and density precision of ±0.001g/cm³, suitable for custody transfer and critical dosing applications.

-

Universal Applicability: Effectively measures a wide variety of media, including liquids, gases, high-viscosity fluids, slurries, and suspensions.

-

Flexible Installation: The design allows for installation without strict requirements for upstream or downstream straight pipe runs, making it ideal for the confined spaces often found in marine vessels.

-

Advanced Connectivity: Features comprehensive output options including 4-20mA, Pulse, RS485 (Modbus-RTU), and HART protocol for seamless integration into PLC and DCS systems.

Specification

| Measured variables |

Mass flow rate, density, temperature |

| Measuring medium |

Gases, liquids, slurries, suspensions, etc |

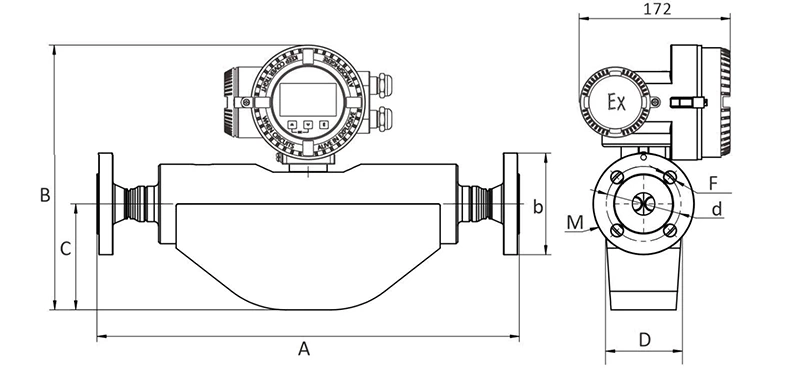

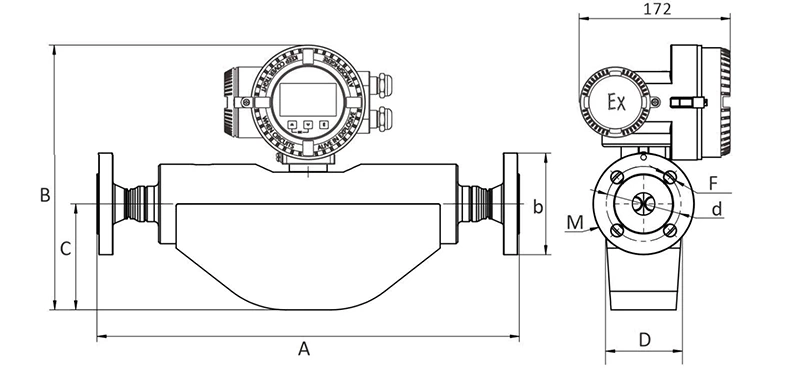

| Nominal diameter |

U-shaped type: DN3~DN150

Micro-bend type: DN8~DN100

Straight pipe type: DN8~DN50

Inverted triangle type: DN1~DN2 |

| Range ratio |

U-shaped type: 10:1

Micro-bend type: 10:1

Straight pipe type: 5:1

Inverted triangle type: 10:1 |

| Temperature measurement range |

(-240~350)℃ |

| Accuracy |

Flow volume: Level 0.15, Level 0.2, Level 0.5

Density: ±0.001g /cm³ ( ± 1kg / m³ )

Temperature: ± 1 ℃ or ± 0.5% × test value, whichever is greater. |

| Repeatability |

1/2 of the accuracy |

| Transmitter output |

(4~20) mA, load resistance ≤ 750Ω |

| Communication |

RS485 , MODBUS-RTU;Hart |

| Pulse output |

Duty cycle: 10%~90%

Pulse frequency: Maximum 10000Hz

Active: Output current 10mA, open circuit voltage 30V |

| Power supply |

24VDC/220VAC |

| Power consumption |

≤ 10W |

| Nominal pressure |

Clamp connection type: Pressure resistant PN16

Flange connection type: pressure resistant PN16, PN40, or PN63 |

| Ambient temperature |

( -40~55 ) ℃ (with display: -25 ℃~ 55 ℃) |

| humidity |

≤95% |

| Protection level |

IP67 |

Applications

The FCC800 flow rate and density measurement device is versatile enough to serve a broad spectrum of industries requiring exact fluid control:

-

Marine & Offshore: Critical for fuel consumption monitoring, bunkering, and ballast water management systems.

-

Petrochemical: Precise measurement of oil products, raw materials, and finished chemical compounds.

-

Food & Beverage: Sanitary measurement of ingredients, syrups, and beverages where hygiene and precision are paramount.

-

Pharmaceutical: Accurate dosing and batching of high-value active ingredients and solvents.

-

Pulp & Paper: Handling of viscous slurries and coating mixtures.

-

Energy & Power: Monitoring of feed water and fuel supplies to maximize plant efficiency.