Understanding Flow Rate in Fluid Dynamics

Fluid dynamics is a fascinating field that delves into the behavior of liquids and gases in motion. Central to this subject is the concept of flow rate, a fundamental parameter that plays a crucial role in various scientific and engineering applications. In this comprehensive article, we will embark on a journey to grasp the intricacies of flow rate in fluid dynamics. Whether you're a student, a researcher, or simply curious about the inner workings of fluids, this article is your guide to understanding flow rate in fluid dynamics.

Introduction

Flow rate, a fundamental concept in fluid dynamics, refers to the quantity of fluid that passes through a given point in a specified period. This parameter holds immense significance across various disciplines, from hydraulic engineering to medical science. By comprehending flow rate, scientists and engineers gain insights into fluid behavior, enabling them to optimize designs and make informed decisions.

What is Flow Rate?

Flow rate, often denoted as Q, represents the volume of fluid that traverses a specific point within a unit of time. In essence, it quantifies the rate at which a fluid flows through a conduit, be it a pipeline, or a river. Understanding flow rate is pivotal for diverse applications, such as predicting water supply, designing efficient ventilation systems, and enhancing combustion processes.

Flow rate is a term used to describe the volume of a fluid that passes through a given point in a given amount of time. It is typically measured in units such as liters per second or gallons per minute. Flow rate is an important concept in many fields, including engineering, physics, and chemistry, as it can be used to determine the efficiency of a system or the amount of material being transported. In fluid dynamics, the flow rate is often used to calculate the velocity of a fluid, which can help predict how it will behave in different situations.

Understanding flow rate is essential for anyone working with fluids, from engineers designing pipelines to chemists studying chemical reactions. By accurately measuring and controlling the flow rate, it is possible to optimize processes and ensure that systems are operating efficiently and effectively.

Flow Rate in Process Control

In process control, the flow rate is a crucial parameter that needs to be constantly monitored and controlled. It refers to the volume of fluid passing through a particular point per unit of time. The accurate measurement and regulation of flow rate is essential for ensuring the efficiency, safety, and quality of various industrial processes.

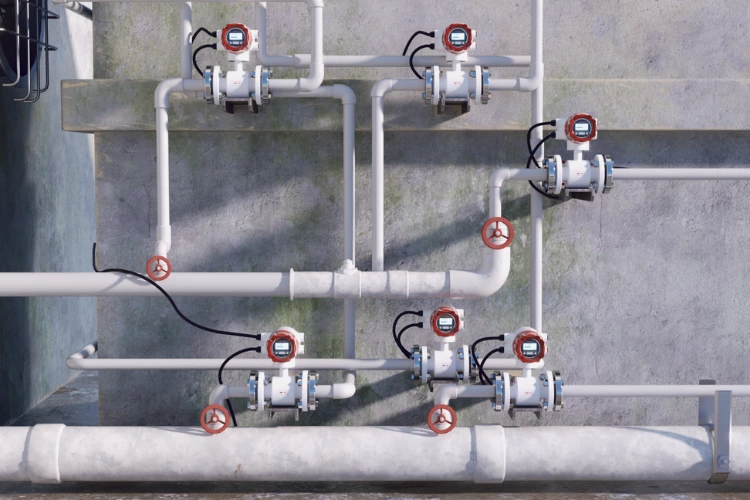

The flow rate can be controlled by adjusting the size of the opening through which the fluid passes, or by using pumps or valves to regulate the pressure. The measurement of flow rate can be done using various types of flow meters such as differential pressure meters, turbine meters, electromagnetic meters, and ultrasonic meters.

Maintaining a consistent and optimal flow rate is critical for achieving the desired results in a process. Too high or too low flow rates can lead to inefficiencies, product defects, and safety hazards. Therefore, process control systems are designed to continuously monitor and adjust the flow rate based on the set parameters.

In addition to ensuring the proper functioning of a process, controlling the flow rate also has economic benefits. It helps to reduce energy consumption and material waste, as well as increase productivity and throughput. Moreover, accurate flow rate measurement and control are often required by regulatory bodies to ensure compliance with environmental and safety standards.

Flow rate is a vital parameter in process control that requires precise measurement and regulation. It impacts the efficiency, safety, quality, and economic performance of industrial processes. Therefore, it is essential to have robust and reliable flow control systems in place to ensure optimal operation and compliance with regulatory requirements.

Factors Influencing Flow Rate

Flow rate is an important parameter in many industrial, environmental, and medical applications. Several factors can influence the flow rate of a fluid, and understanding these factors is crucial for optimizing the performance of systems that rely on fluid flow.

One of the most important factors that affect flow rate is the viscosity of the fluid. Fluids with high viscosity tend to flow more slowly than those with low viscosity. This is because high-viscosity fluids have a greater resistance to flow due to internal friction between their molecules. Temperature can also affect viscosity, as higher temperatures tend to decrease viscosity and increase flow rate.

Another factor that can influence the flow rate is the pressure gradient across the system. A pressure gradient is a difference in pressure between two points in a fluid system, and it determines the direction and magnitude of fluid flow. In general, a larger pressure gradient will result in a higher flow rate, as the fluid is pushed more strongly in the direction of lower pressure.

The geometry of the system can also play a role in determining the flow rate. Systems with narrow passages or obstructions may experience greater resistance to flow, resulting in a lower flow rate. Conversely, systems with wider passages or smoother surfaces may experience less resistance and a higher flow rate.

The properties of the fluid itself can also affect the flow rate. For example, fluids with high density or high surface tension may have a lower flow rate than those with lower density or surface tension. The presence of impurities or particles in the fluid can also impede flow and reduce the overall flow rate.

Finally, external factors such as gravity or magnetic fields can influence the flow rate in certain systems. For example, gravity can cause fluids to flow downhill more quickly, while magnetic fields can be used to control the flow of magnetic fluids.

In a word, there are many factors that can influence the flow rate of a fluid, including viscosity, pressure gradient, system geometry, fluid properties, and external factors. By understanding these factors and optimizing them as necessary, engineers and scientists can design systems that achieve the desired flow rate for their specific applications.

Equations and Calculations

The calculation of flow rate depends on the nature of the fluid flow. For steady, incompressible flow, the volumetric flow rate (Q) can be calculated using the equation:

Q=A⋅v

Where:

Q is the volumetric flow rate,

A is the cross-sectional area of the conduit,

v is the velocity of the fluid.

For compressible fluids or situations where the cross-section changes along the flow path, more complex equations are utilized. These calculations provide a quantitative understanding of flow rate dynamics, aiding engineers in designing systems with optimal performance.

Measuring Flow Rate

Measuring flow rate is an essential process in many industries, including manufacturing, oil and gas, and water treatment. Flow rate refers to the amount of fluid that passes through a system per unit of time. Accurately measuring flow rate is critical to ensure that processes operate efficiently and safely.

There are several methods for measuring flow rate, including differential pressure devices, positive displacement meters, electromagnetic meters, and ultrasonic meters. Differential pressure devices measure the pressure difference across a restriction in the flow path and use this information to calculate the flow rate.

Positive displacement meters measure the volume of fluid passing through the system by counting the number of times a chamber is filled and emptied. Electromagnetic meters use Faraday's law of electromagnetic induction to measure the velocity of the fluid passing through the meter. Ultrasonic meters use sound waves to measure the velocity of the fluid.

Each method has its advantages and disadvantages, and the choice of method depends on the specific application. Factors such as fluid viscosity, pressure, temperature, and flow rate range must be considered when selecting a flow meter.

In addition to selecting the appropriate flow meter, it is also important to ensure that the meter is installed correctly and calibrated accurately. Proper installation includes ensuring that the meter is installed in the correct orientation, that there is no air or debris in the flow path, and that the meter is grounded to prevent electrical interference. Calibration involves comparing the output of the flow meter to a known standard and adjusting it if necessary.

Regular maintenance of flow meters is also essential to ensure accurate measurements. This includes periodic cleaning of the meter and verifying that it is still within calibration.

Measuring flow rate is a critical process in many industries. The selection, installation, calibration, and maintenance of flow meters are all important factors in ensuring accurate and reliable measurements. Proper measurement of flow rate can help improve process efficiency, reduce costs, and enhance safety.

Types of Flow

Fluid dynamics categorizes flow into several types based on characteristics like velocity distribution and predictability. Steady flow maintains a constant pattern over time, making it easier to analyze and predict. Conversely, unsteady flow exhibits fluctuations and irregularities, often encountered in scenarios like turbulent water currents or combustion processes.

Steady vs. Unsteady Flow

Steady flow offers simplicity, aiding engineers in designing stable systems. However, real-world scenarios often involve unsteady flow due to dynamic factors. Unsteady flow's complexity requires advanced mathematical tools and simulations, enabling us to grasp and manage its intricate behavior.

Laminar Flow: A Closer Look

Laminar flow occurs when fluid particles move in parallel layers, exhibiting minimal disruption. This smooth flow is characterized by predictable motion and is often encountered in low-velocity situations. Understanding the transition from laminar to turbulent flow is crucial, as it impacts efficiency and energy consumption in various applications.

Turbulent Flow: Unraveling the Chaos

Turbulent flow, on the other hand, is marked by irregular fluctuations and mixing. This chaotic behavior arises from the interaction of various factors, such as fluid viscosity and flow velocity. While turbulent flow may seem disorderly, it plays a pivotal role in mixing substances, enhancing heat transfer, and promoting chemical reactions.

Bernoulli's Principle and Flow Rate

Bernoulli's principle is a fundamental concept in fluid dynamics that explains the relationship between the speed of a fluid and its pressure. According to this principle, as the speed of a fluid increases, the pressure within the fluid decreases. This relationship has important implications for many engineering applications, including the design of aircraft wings, the operation of wind turbines, and the flow of fluids through pipes and channels.

One key application of Bernoulli's principle is in the calculation of flow rate, which is a measure of the volume of fluid that passes through a given point in a certain amount of time. By understanding the relationship between fluid speed and pressure, engineers can use Bernoulli's principle to predict and control the flow rate of fluids in a variety of settings.

One common example of this principle in action is in the design of pipe systems for transporting fluids. By controlling the diameter of the pipe, engineers can manipulate the speed of the fluid and therefore the pressure within the system. This allows them to optimize the flow rate for different applications, such as water distribution or oil and gas transport.

Another important application of Bernoulli's principle is in the design of aircraft wings and other aerodynamic structures. By shaping the wing to create areas of high and low pressure, engineers can generate lift and control the direction and speed of flight. This principle also applies to wind turbines, where the shape of the blades is optimized to maximize energy output by controlling the flow rate of air through the system.

In addition to these practical applications, Bernoulli's principle has important implications for our understanding of fluid dynamics at a fundamental level. By explaining the relationship between fluid speed and pressure, this principle provides a foundation for many other concepts in fluid mechanics, such as viscosity, turbulence, and laminar flow.

Bernoulli's principle is a powerful tool for engineers and scientists working with fluids in a wide range of applications. By understanding this principle and its implications, we can design more efficient and effective systems for transporting fluids, generating energy, and exploring the complex dynamics of fluid motion.

Applications in Engineering

Understanding flow rate is paramount in engineering disciplines. In hydraulics, it governs the efficiency of water distribution systems. In aerospace, it impacts the design of propulsion systems. By leveraging flow rate insights, engineers optimize processes, enhance performance, and minimize resource wastage.

FAQs about Understanding Flow Rate in Fluid Dynamics

Q 1: What is the definition of flow rate?

Flow rate refers to the volume of fluid passing through a specific point per unit of time. It quantifies the rate of fluid motion and plays a pivotal role in numerous scientific and engineering applications.

Q 2: How is flow rate calculated?

Flow rate is calculated by dividing the volume of fluid passing through a point by the time taken. Mathematically, it is expressed as the product of the cross-sectional area of the conduit and the fluid velocity.

Q 3: What are the SI units of flow rate?

Flow rate is measured in cubic meters per second (m³/s) or its submultiples, such as liters per second (L/s) or milliliters per second (mL/s).

Q 4: Can flow rate change in a pipeline?

Yes, flow rate can change in a pipeline due to factors like changes in pressure, fluid properties, or blockages within the conduit.

Q 5: How does viscosity affect flow rate?

Viscosity, a measure of a fluid's resistance to flow, impacts flow rate. Higher viscosity fluids experience slower flow rates compared to low viscosity fluids under the same conditions.

Q 6: What instruments measure flow rate?

Flow rate is measured using instruments like flowmeters, Pitot tubes, and ultrasonic devices. These tools employ various principles to provide accurate flow rate readings.