Coriolis mass flowmeter

Mass Flow Meter is a new type of advanced flow measurement instrument and has been rapidly developed in the world. It has been widely used for process detection and custody transfer measurement in many industries such as petroleum,petrochemical, chemical, pharmacy, marine, pharmaceutical, municipal, paper, food and energy and so on. It has been highly valued by the flow research community and welcomed by users at home and abroad.

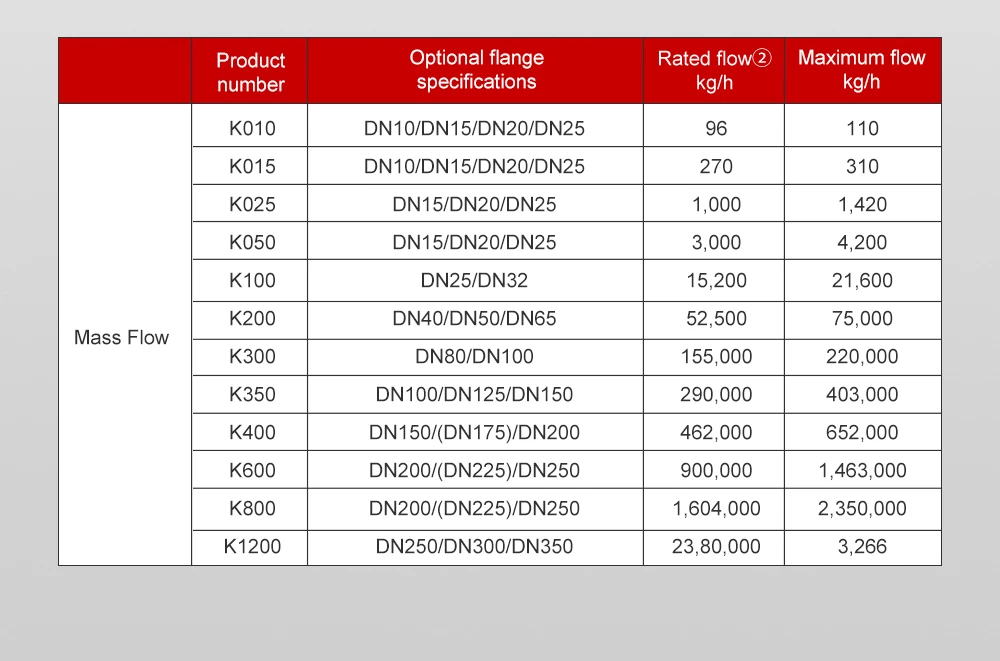

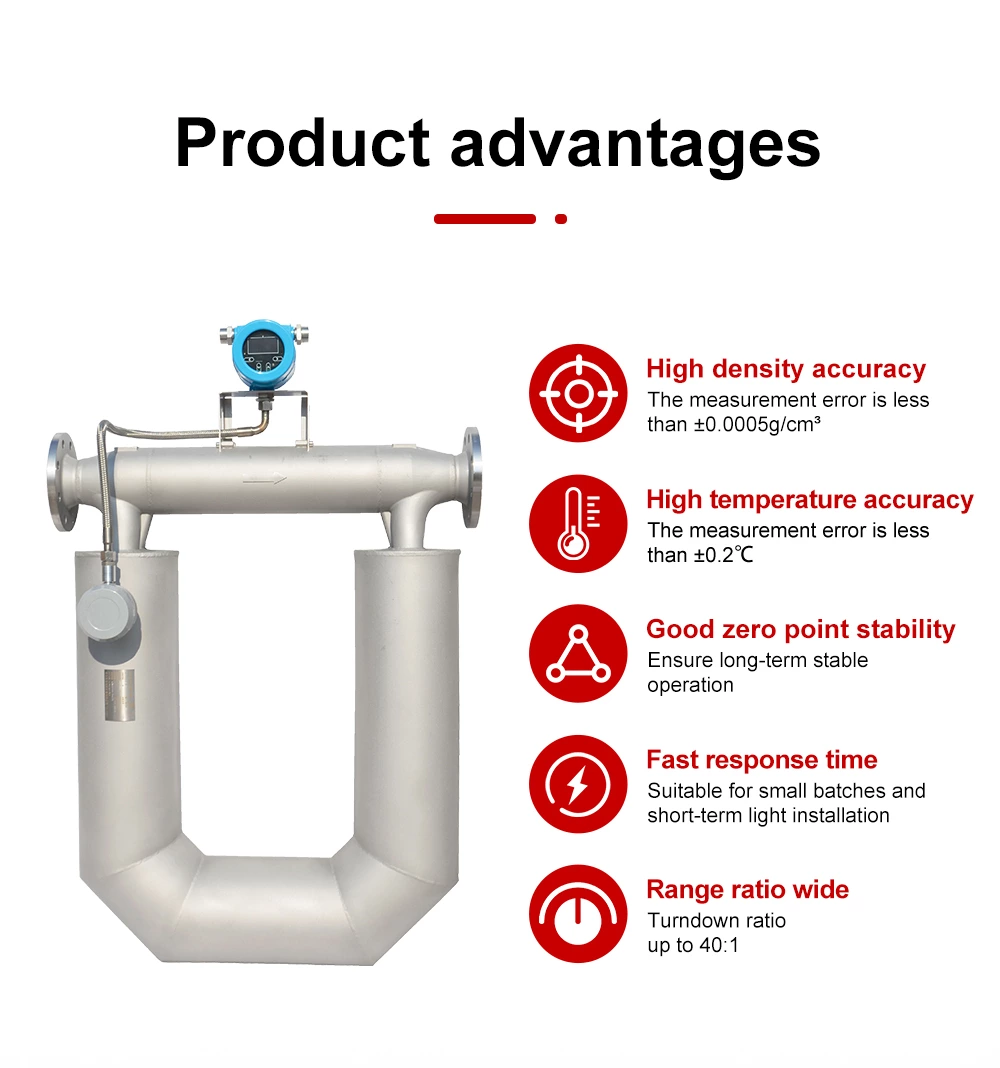

K series Sensors are used in conjunction with BPM Transmitters to provide accurate instantaneous flow, flow totals, and real-time monitoring of density and temperature.

Characteristics

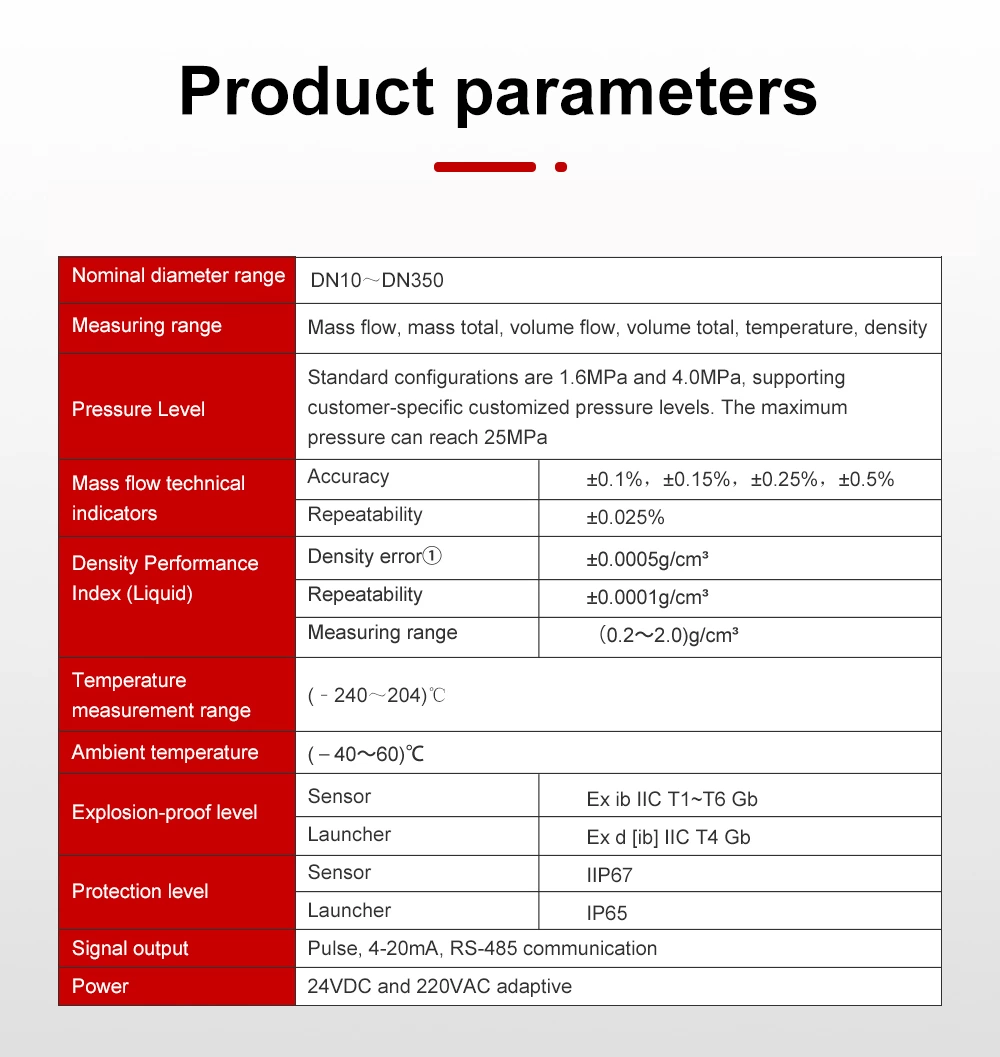

Pipe diameter:DN10-DN350

Measuring range:Mass flow, mass total, volume flow, volume total, temperature, density

Accuracy:±0.15%,±0.2%,±0.5%

Repeatability:±0.025%

Temperature measurement range:(﹣240~204)℃