Application Case | Nine electromagnetic flow meters

Application Case | Nine electromagnetic flow meters + instrument cloud saved more than one million yuan in one year?!

"Now, the entire workshop can save nearly 200 tons of water usage every day. More importantly, due to water conservation, the cost of wastewater treatment has decreased significantly. Taken together, these two expenses have been reduced by over 100,000 yuan per month on average, which translates to more than one million yuan saved in a year," Mr. Wu Zhao said.

The third workshop, overseen by Mr. Wu Zhao, is located in the Shaoxing Keqiao green printing and dyeing industrial cluster, with an annual output of 13,500 meters of woven printing and dyeing fabrics and over 80,000 tons of knitted printing and dyeing fabrics.

In recent years, this printing and dyeing industrial cluster has continuously increased its environmental protection investment and steadily pushed forward green transformation through measures such as optimizing dyeing and finishing processes, updating water-saving technologies, and equipping with advanced environmental protection equipment. To further strengthen waste reduction at the source, the third workshop introduced the MEACON process automation solution in 2023.

"Our previous water usage methods were relatively extensive. After installing nine electromagnetic flow meters, we can accurately monitor water usage and achieve fine-grained savings. Moreover, within a month, we basically recovered the procurement cost of the equipment," Mr. Wu Zhao said. In his view, the changes are not just reflected in "cost savings".

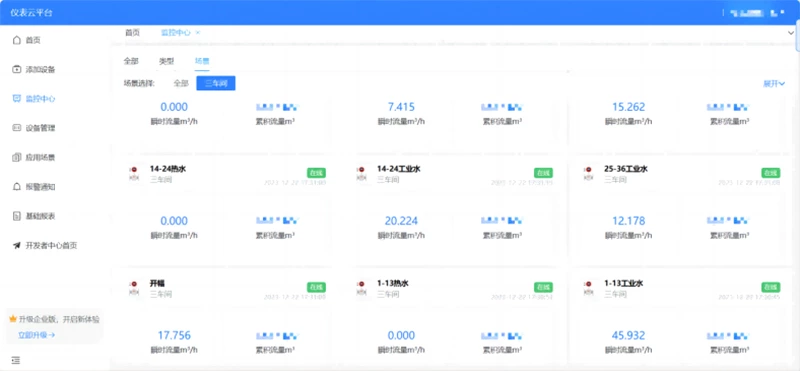

On site, Mr. Wu Zhao took out his phone, opened the instrument cloud APP, and began checking the operating status of all equipment in the factory. "With this instrument cloud, our management model has also changed. Remote monitoring and data viewing, as well as abnormal alerts, mean we no longer need to send people to run around the factory to check. The instrumentation cloud has improved our management and operational efficiency."

The data analysis provided by the instrument cloud has brought tangible value to Mr. Wu Zhao's workshop.

"After installing electromagnetic flow meters, the instrument cloud records and outputs a large amount of data. By analyzing these data, we can continuously optimize and adjust water usage during the production process, further improving production efficiency and product quality. I believe this is the ‘magic’ of digital," Wu Zhao said